Stainless-Steel Reactors

Jacketed / limpet-coil reactors for chemical & API plants with anchor / turbine agitation.

Heat Exchangers

Shell & tube heat exchangers designed for steam, thermal oil and solvent applications.

Receivers & Storage Tanks

Custom SS-316L receivers with GMP finish for solvent handling & buffer storage.

Condensers

High-efficiency condensers for distillation, solvent stripping and vapor recovery systems.

Column & Packed Towers

Structured / random packing options for distillation, absorption & stripping operations.

Reboilers & Process Vessels

Standardized vessels for heating, boiling and process utilities.

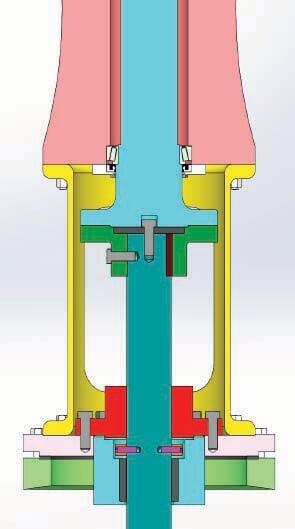

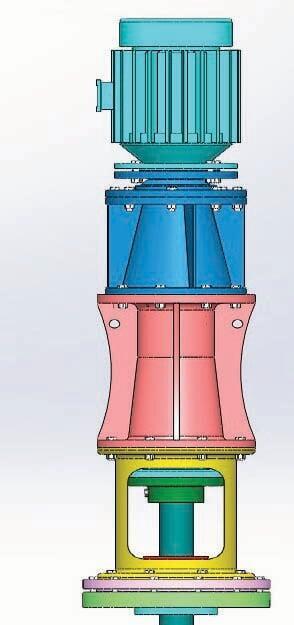

Advanced Reactor Drive Technologies

We offer high-performance reactor agitation systems designed for critical mixing applications in chemical & pharmaceutical industries.

Our drive technologies ensure stable torque output, longer gearbox life and consistent batch quality.

High-Torque Helical Gear Drives – optimized for vacuum & high-viscosity operations

Quick Seal maintenance – Quick seal maintenance mechanism from top without Batch interruption.

Mechanical Seal Integration – double/single seal systems for solvent-rich environments

Variable Speed Drive Control (VFD) – precise rpm control for scale-up consistency

Energy-Efficient Drive System – reduced power load during high-viscosity startup

Why Choose B&G Engineering

High Durability

SS-316L / Duplex options with corrosion resistance.

Custom Engineering

Tailor-made vessels for your exact process.

GMP Finish

Hygienic-grade polishing for chemical & pharma plants.

Fast Project Turnaround

Accelerated design + fabrication workflow.

Ready to Build High-Performance Chemical Equipment?

Our experts can design and manufacture the right solution for your plant.