Multi-Effect Evaporator (MEE)

Designed for high evaporation rates with low steam consumption.

Forced Circulation Evaporator (FCE)

Handles viscous, scaling & corrosive feeds.

Falling Film Evaporator (FFE)

High heat transfer with minimal residence time—ideal for heat-sensitive products.

ATFD / Thin Film Dryer

Drying system for achieving solid output with <1% moisture.

Distillation & Solvent Recovery Systems

Packed-column distillation for chemical, pharma & solvent purification.

Stripper Columns & Reboilers

For VOC removal, solvent stripping & heat transfer systems.

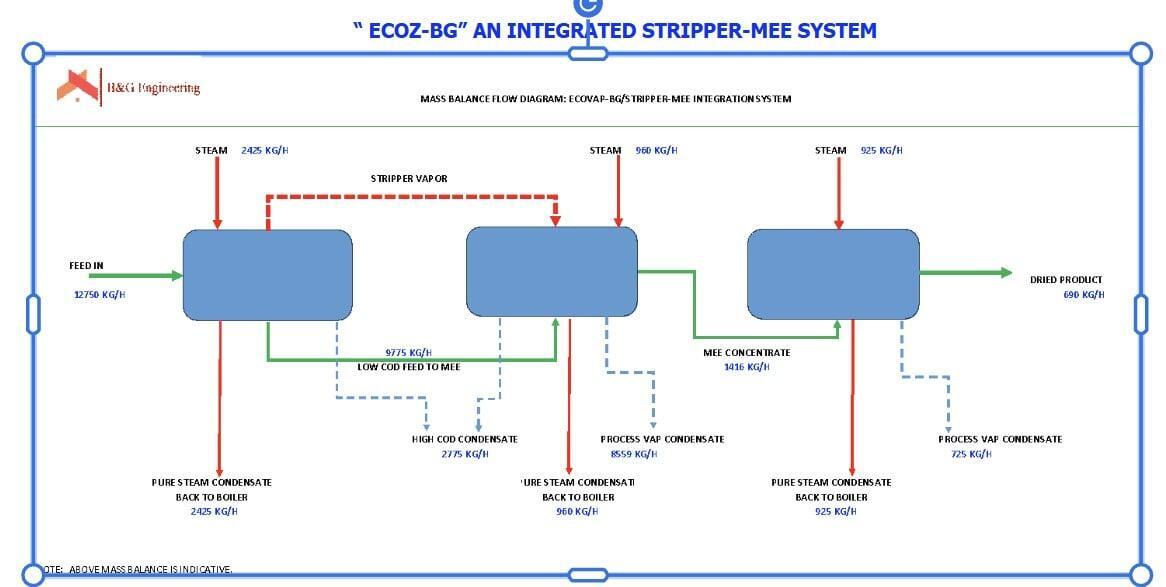

Integrated MEE Vapor Utilization Technology (Above 200 KLD)

Our Multiple Effect Evaporators incorporate a unique vapor integration system where stripper vapor is reused as a heating source for the calandria.

This significantly improves thermal efficiency and reduces overall live steam consumption.

Key Advantages

Reduced steam requirement

Lower operational cost

Enhanced calandria heat transfer stability

Improved system efficiency for high-volume effluent loads

Where It’s Suitable

Ideal for MEE installations greater than 200 KLD, especially in high TDS/high COD industrial effluent treatment.

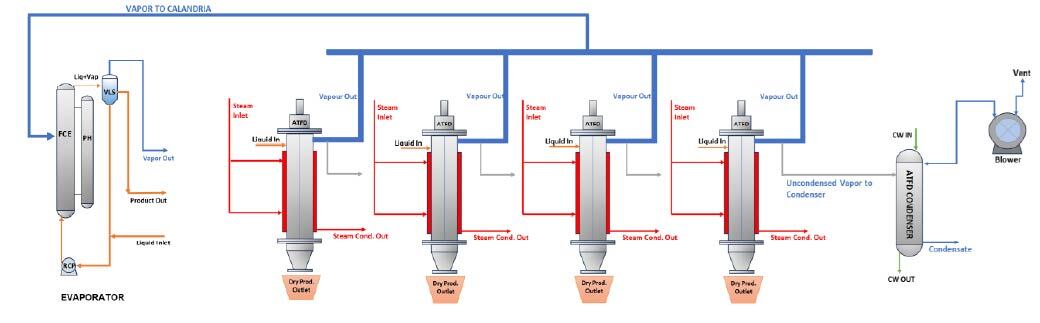

ATFD Common Vapor-to-Calandria Reuse System (4+ Units)

For plants operating four or more ATFDs, we integrate a common vapor reuse system where the waste vapor from multiple ATFDs is redirected to the calandria for secondary heating.

Benefits

Energy recovery from existing process vapor

Reduced boiler load

More uniform evaporation performance

Lower operating cost in high-solids concentration applications

Why It Works

By combining vapor from multiple ATFDs into a single header, the system ensures stable, balanced heating and greater thermal efficiency across the evaporation process.

Energy-Optimized Evaporation & Drying Systems

Engineering Capability

✔ MS/SS/DU/F.R.P construction options

✔ 3D modeling of entire plant

✔ NDT & hydro testing before dispatch

✔ Energy-efficient steam & condensate recovery

✔ Compliance with PCB & ZLD norms

Industry Applications

Looking to improve your plant’s evaporation performance?

Our team can design a complete ZLD solution.